Product - Pressure Sensitive Adhesive (PSA)

Pressure Sensitive Adhesive (PSA)

Offset Inks are mainly used in the printing of newspapers, book, magazines, paper-based packaging, posters and catalogues. We are providing 4 types offset inks available in the Toyochem, which are Sheetfed Ink, Web Heatset Ink , Web Offset Ink and Web Coldset Ink.

Type Of Offset ink

SHEETED INK

WEB OFFSET

WEB HEATSET

WEB COLDSET

Offset Ink

TOYOCHEM SPECIALTY CHEMICAL SDN. BHD. (TSC) strongly believes in product development and is well supported by our parent company in Japan. Technically equipped with state-of-the-art laboratory equipment, our highly skilled technical team provides all the necessary technical support by carrying out new innovations, product development and enhancement of ideas in order to stay ahead in the field.

We are committed to provide outstanding technical service and support to our customers by:

- Evaluating press type, printing & lamination conditions to ensure optimized performance.

- On site monitoring and trouble shooting.

- Assist customer to check quality of various substrate such as Coated and Uncoated paper to minimize problems associated of various substrates quality such as paper pH, pick test, oil absorption and etc.

In the customization field of Colour Matching or Spot Colours, we have a group of experienced colour matchers to meets customer’s requirement with highest level of accuracy & consistency.

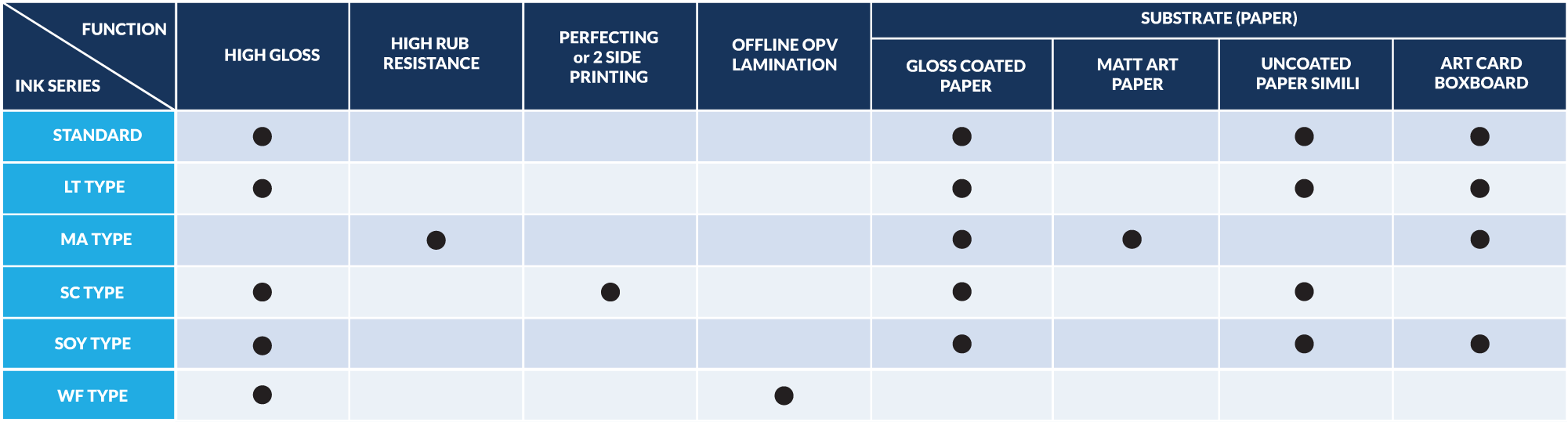

Type Of sheeted ink

TK PRIME COLORS

TK UNI PRO COLORS

TC MAX COLORS

Sheeted Ink

Toyochem has an experienced team of colour matchers that are able to provide accurate matching to your required color on selected paper type. As more sheetfed inks are used in packaging printing, LAB values and delta E have been the communication language for colors. Upon request from our customers, our spot colors matched can be verified with the targeted delta E.

1 Poor – 10 Excellent

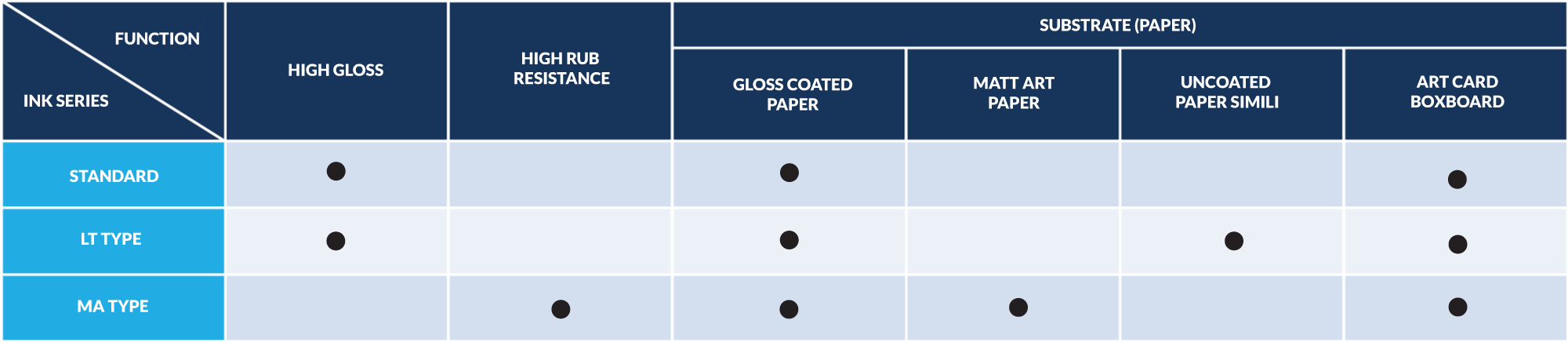

TK Prime colours

A special designed and formulated sheetfed offset ink through many interactions and comprehensions between valued customers and Toyochem. TK Prime offers more superior ink properties enabling a well-balance performance on the press with excellent color density, gloss, ink water-balance, press stability and printability.

- Contain aromatic free solvent.

- Comply to RoHS, EN-71, ASTM 963 and etc.

- Contain >20% Vegetable Oil.

Recommended for Application

TK UNI PRO colors

Suitable to be printed on wide range of substrate from coated to uncoated paper. Suitable for most ofjobs including publication and packaging job.

- Contain aromatic free solvent.

- Comply to RoHS, EN-71,ASTM 963 and etc.

- Contain >20% Vegetable Oil.

Recommended for Application

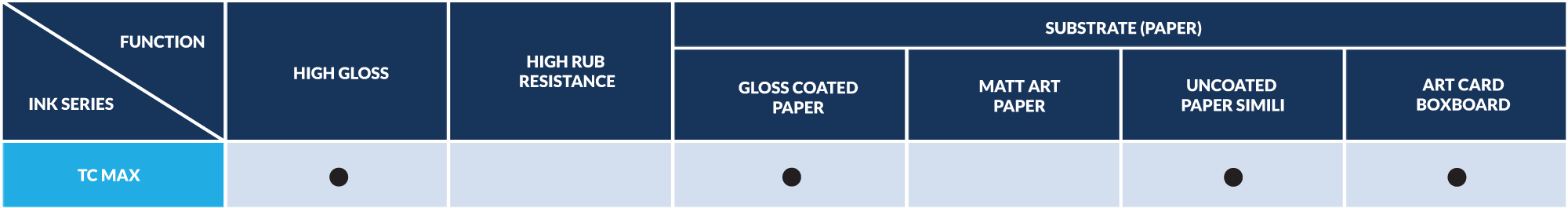

TC MAX Colors

A mild sheetfed ink series that meet most general purpose requirements on the press and substrate.

Recommended for Application

MO O/S Colors

A wide range of special colors or spot colors are available, many of which were tailor-made to customer’s specifications.

Product Available :

- Spot color — for color matching that in Pantone System or customer’s reference.

- Metallic inks.

- Fluorescent inks.

‘ Foil inks.

- Light fastness resistant inks.

- High rub inks.

- Wax free inks — for lamination or offline overprint.

(All above products comply to RoHS, EN-71, ASTM 963 and etc.)

matched can be verified with the targeted delta E.

MV O/S Colors

Special Colors or Spot Colors for UV Offset Printings, that can be tailor made to customer specification.

Type overprint Varnish

MO-3301 Matt Overprint Varnish

For general use.

TC-5 Matt Overprint Varnish

Provide "high-matt' finishing.

TC-15 Gloss Overprint Varnish

- Excellent gloss finishing.

TC-23 High Scuff Overprint Medium

- High rub resistance overprint varnish.

overprint Varnish/ medium

Overprint varnish (OPV) is coating applied on an already printed sheet or web. The primary reasons for applying an OPV are gloss enhancement, stain resistance, edge fusion resistance, burnish or scuff resistance, and resistance to discoloration from absorption of impurities in the environment.

A wide range of conventional oil-based air drying type of overprint varnish and medium are available with following features.

- Good gloss (except for Matt Overprint Medium).

- Excellent drying properties.

- Good yellowing resistance.

- Suitable for wet-on-wet (In-line) and wet-on-dry (offline) application.

, Comply to RoHS, EN-71,ASTM 963 and etc.

Type uV ink

Fast curing with less UV energy.

Compliant with ISO 2846-1 to support printers achieving ISO 12647-2. Higher gloss level compared to regular UV ink.

Better de-inking property compared to regular UV ink that promote paper recycling.

Obtain conventional sheetfed print quality benefiting from UV print advantages, instant curing, fast post-press, no spray powder, no offset problems and etc.

Recommended to use on coated, sheetfed print quality instead of sheetfed print.

.

Recommended for non-absorbent substrates such as PP, PE, PET, PVC and etc.

Fast curing properties.

UV Ink for offset ink

UV ink dry through a photomechanical process. The ink is exposed to ultra-violet light as it is printed, immediately turning from a liquid to a solid with very little evaporation of solvents and almost no absorption of the ink into the paper stock. You can print on most substrates using UV ink.

web coldset ink wKNU newsblack

WKNU PROCESS COLORS (3 PROCESS COLORS – YELLOW , MAGENTA AND CYAN)

Newspaper had come a long way since the turn of the century when they were printed only in black and white and often consisted ofjust a single sheet. Today, state-of-art printing machine can run up to 80,000 iph, delivering multiple-section broadsheet publications in multiple colors.

Toyochem has kept abreast of the advancement in this technology and has the opportunity to work very closely with some of the largest newspaper companies in the region. The knowledge and expertise gained has enable Toyochem R&D team to develop products that combine a wealth of practical applications with cost-effectiveness for the sophisticated processes involved.

Web heatset ink

WEB DRY MILENIA NEO SERIES

Close knit supplier customer relationships have been the key to the creation of the Web Dry Milenia Neo Series. The invaluable feedback from many press trials has resulted in the formulation of a “Printer Ink” that is extremely user friendly. Once in the duct, this unique ink will run to the ‘last drop’. Its many benefits include excellent color strength, ultra-low temperature drying, as well as excellent gloss, dot sharpness and ink transferability.

- Excellent gloss and drying properties.

- Excellent ink/water balance.

- Excellent dot reproduction.

- Excellent stability on the press with minimal piling on the blanket.

- Excellent printability and mileage.

- Contain >20% vegetable oil.